|

Page 2 of 2

Five case studies: NGOs, Governments and businesses collaborate to build air quality monitoring capacity

A range of air quality monitoring projects has been implemented over the last decade in developing

countries. This report explores the impacts of such projects, focusing on case studies from five countries:

Morocco, the Philippines, Indonesia, India and Malaysia. These projects were selected and profiled in late

2005.

In all the case studies except for the Indian fuel testing project, imported air-quality monitoring equipment was crucial to the programmes’ successes. Such equipment is not manufactured to any significant degree in developing countries at this point. (In the Indian case, advanced imported equipment for fuel testing would have increased the speed and efficiency of testing, but project funding limits forced the investigators to use older, indigenously manufactured equipment.)

With the vast majority of their sales in the developed countries, manufacturers still do not see much of a market in the developing world and have little incentive to license their technology to producers in developing nations. While manufacturers’ instruments and monitoring systems source sub-components worldwide, virtually all technologically advanced components are sourced from developed countries, and virtually all assembly and testing is performed in the manufacturers’ domestic factories. This could change in the future if the volume of purchases in developing countries increased to the point where manufacturers could achieve the economies of scale necessary to outsource or franchise production to manufacturers in developing countries.

Overall it seems to be clear that most analytical technology used in the developing world for environmental purposes is imported from developed nations. However, like much of the broader environmental industry that involves air, waste, wastewater, solid waste, recycling and remediation, there are significant service and labour components involved in almost every environmental project. So often, the importation of a piece of sophisticated machinery involves the employment and training of a large number of individuals and contributes to the building of institutions. An example exists in the Manila project where a USD2.3-million project funded by the Asian Development Bank involves the purchase of just USD170 000 worth of monitoring equipment, with most of the remaining amount used for data collection and analysis by local project team members.

Click here for full text

|

Submitted by Singapore

AIM

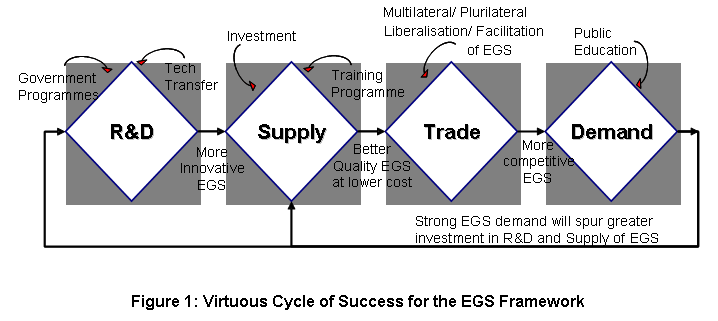

This paper seeks CTI's endorsement on a work programme framework for environmental goods and services (EGS) in APEC.

...

Submitted by Singapore

AIM

This paper seeks CTI's endorsement on a work programme framework for environmental goods and services (EGS) in APEC.

...